One thing is clear: The year 2020 was, let us just say, unusual. In fact, it was challenging for the economy and societies all over the world, almost like never before. The year, to say the least, was full of uncertainties and restrictions within the “new normal”. For large parts of the plastics processing industry, the year had already gotten off to a bad start, with clear signs of an economic slowdown – especially the automotive industry, which was already suffering from a decrease in demand. But judging by what followed, some people were probably wishing that they had pre-pandemic problems again. Because things became much worse as coronavirus came along – from lockdowns and shutdowns to logistical issues to lack of personal protective equipment. The fact that almost all the attendance events were cancelled was in itself a minor evil.

The crisis year, however, also encouraged activities that would have been unthinkable up to that point, for instance, virtual conferences, and “Balcony Singing for the Plastics Industry”, which was launched by plas.TV.

But beyond that, the world continued to turn, even if not in its usual, roundabout way. The plastics industry managed to survive and became inventive. Plastics’ producers of raw materials had to deal with various cutbacks and forces majeures, packaging went the cucumber way, and in the ambit of recycling, aspirations collided with reality.

The wheel of personnel also kept turning: In VIP News you can look back on well-ordered transitions and surprising changes. Meanwhile, let Click Stars tell you about our most prominent articles of the year, besides, of course, polymer price reports and coronavirus-related news.

The new year is bringing us big bags of hope – of overcoming the pandemic, of the vaccination succeeding, and of a gradual return to “normal life”. Last but not least, we wish you only one thing at the moment: Stay Healthy!

Your PIE Editorial Team

The coronavirus pandemic, which disrupted businesses all over the world this year, also left its mark on the plastics industry – first in China and then around the world. As companies in the east started hoping for increased post-pandemic demand, businesses in Europe started going into lockdown.

Machine manufacturer Engel was one of the first in the industry to stop production. Soon after, Shell imposed a construction freeze on a petrochemical complex to protect 7,500 workers from Covid-19. Logistics collapsed after coronavirus-induced chaos at the borders.

By the middle of the year, the downward trend that had already been documented by a flash survey conducted by PIE started showing up in balance sheets. There was, however, also a wave of helpfulness during the crisis, and some companies even benefitted during it. Wherever possible, creativity and determination were used to switch over to producing medical technology and PPE. Masks and gloves, however, have only added to the plastics waste crisis.

The comparatively moderate summer was followed by an increase in the number of cases during the second wave, and gave rise to various lockdown scenarios all over Europe, with unpredictable consequences for the economy.

“Balcony singing for the plastics industry” during the coronavirus pandemic – this was the idea of Guido Marschall, founder of Germany’s plas.TV who used his online channel for interviews. Under the name “Plastics unite(d)” he talked to lots of key players from the European and international plastics industry. By showing people that they are not alone in dealing with the pandemic’s impact on their businesses, as well as their health issues, the moderator both encouraged people through his show, and gave them confidence.

Thanks to the cooperation with KI Group, PIE readers could watch these five-minute programmes in English at www.pieweb.com.

Since the outbreak of Covid-19, positive properties of plastic products have regained the public’s attention. Medical supplies, face masks, disposable gloves and food-protection packaging became extremely important. Marschall hopes that this positive image of plastics remains after the crisis is over – and so do we!

Everything was in place for an eventful and successful exhibition year in 2020. But trade fair organisers were hit harder by the coronavirus pandemic than almost any other sector. The postponement of “Chinaplas” in Shanghai was only the beginning, with Covid-19 hitting Europe soon after, leading to an endless series of postponements and cancellations. In the wake of this, organisers fought a battle that could not be won.

While “Fakuma” managers, for instance, were still negotiating hygiene and safety concepts with the authorities, leading exhibitors had long since put the matter behind them. “No active participation” were the words used to express this: although the booked exhibition floor space was to be kept, companies only planned to fill it with roll-ups; experts were not made available on site for discussions. However, it soon became clear that exhibitors were not the only ones to stay away from trade fairs; visitors could not attend either. As a result, Fakuma did not take place as planned. Across Europe, only the Polish “Plastpol” in Kielce opened its doors.

Elsewhere, trade fair organisers developed new concepts in response to revenue losses that threatened their very existence, aiming to bring exhibitors and visitors together online or in hybrid formats going forward. Above all, however, there was the hope of things getting back to normal as soon as possible. And so, at least the exhibitors’ advisory board of the “K” continued its work as usual in October 2020 and set the course for "K 2022".

From the very beginning, the PIE event calendar has provided up-to-date information on all changes – and continues to do so.

Up until the spring, everything was seemingly fine: “According to the surveys PIE conducts for its prices, the turbulence in the world of polymers has so far been fairly restrained in Western Europe,” wrote PIE in April 2020. This period of calm, however, did not last very long, as weak ordering of parts and products soon forced converters to cut back production.

By the summer, demand had almost completely collapsed in some sectors. Soon after, this resulted in expected price distortions, because polymer production was approaching a level that was no longer economically viable. Despite production cutbacks, inventories were enormous. On the other side of the Atlantic, low oil prices presented shale gas companies with a major problem, while in Europe, a fundamental change in the market for LLDPE stretch-film materials had a big impact.

Problems associated with the pandemic accompanied us with great intensity into the autumn. The hope of a respite gave way to a hurricane season in the US, which turned out to be the most severe since 2005. As if that was not enough, a bottleneck occurred with PVC, and above all with PU, right in the middle of the recovery phase.

This brief expedition through the world of feedstocks is coming to an end with a number – the number 36 – because that is how many forces majeures were registered by PIE over the course of the year. Just as many as in the previous year, but fewer than in the years when the criticism from plastics converters was boiling over.

Consumers wanted maximum product protection well before the start of the pandemic – but by all means not with plastic packaging! The cucumber, which can naturally get by without a protective sheath of plastic, is the first to be affected. However, many other products don’t have the same natural design.

The packaging industry is thus moving increasingly towards hybrid solutions. Plastic film is coupled with a cellulose layer to combine product protection with a “non-plastic look”. Consumers approve, unaware that many composite materials are difficult to recycle. This is also true for black plastic packaging, but new pigments offer better solutions here.

Other trends this year: Monomaterial instead of multilayer as well as an increased use of recyclate in accordance with the sustainability agendas of many brand owners. This trend has also been fuelled by the EU-wide plastics tax.

Alongside the construction industry, the packaging industry is still one of the heavyweights in the field of plastics processing, with a global value of almost USD 1 tn. But the latest regulations – such as the recent plastic bag ban in Germany – and national SUP laws as in UK, Spain, Germany or China will burden packaging even more.

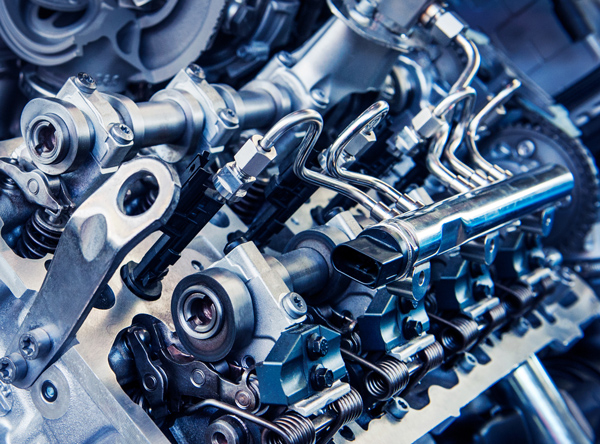

Audi 9,500, BMW 6,000, Continental 13,000, Daimler 10,000 to 15,000, MAN 9,500, Schaeffler 4,400, VW 20,000, ZF Friedrichshafen 15,000 – about 80,000 jobs will be lost in the next few years at car manufacturers and major car suppliers alone. That’s 10% of those directly employed in the German car industry. The reasons given are overcapacity, the transformation to e-mobility and the pandemic.

Although new jobs are also being created, for example at VW for software and e-mobility, German carmakers are generally making the most of their home base. The old combustion technology is to be relocated abroad, while the promising business with e-vehicles will remain in Germany.

The industry has suffered plant shutdowns, slumping sales and massive layoffs. Insolvencies such as those of suppliers Novares and Techniplas were only the tip of the iceberg. By 2019, the automotive industry was already in a slump. Experts predicted in spring 2020 that production of passenger cars and light commercial vehicles would fall by 15% to 77m vehicles worldwide. According to the German Association of the Automotive Industry, production in Germany fell from almost 500,000 passenger cars in 2018 to probably less than 300,000 in 2020.

There was some optimism recently, after figures at the end of Q3 were edging closer to the same period of 2019. Consultants still estimate, however, that profits at the top 20 global automotive OEMs will decline by around USD 100 bn in 2020, roughly a drop of six percentage points from two years ago. European associations called on the EU Commission for a post-crisis recovery plan.

Also: For almost 70 years now, the “IAA” trade fair has been firmly connected with Frankfurt – it will now be held in Munich, planned to run from 7 to 12 September 2021.

For some people, chemical recycling of plastics is the ideal way to combat global littering of plastics, while also saving on fossil raw materials. For others, chemical recycling is a misguided route, because of ecological and economic concerns, while being nothing more than a diversionary tactic.

Be it because of the hype or not, EU’s recycling quotas must be met, as demanded. Keeping the same in mind, the plastics industry has been particularly active in establishing cooperation agreements along the value chain – a cross-industry consortium has been founded to increase PET recycling, while leading competitors are working together on creating closed PS cycles.

In 2020, as expected, no major plants for chemical recycling went onstream – their market maturity is still way off. LyondellBasell, nevertheless, started up a pilot plant in Italy, and almost all chemical companies – like BASF, Borealis, Ineos, Sabic, Total, Repsol and Versalis – have at least for now announced promising projects for producing pyrolysis oil or other “renewables”.

Meanwhile, due to Covid-19, the European recyclate market came under massive pressure, with virgin materials becoming rather cheap. Support for mechanical recycling and re-use systems was the new guiding principle. It remains to be seen whether, at some point in the future, this will also improve the image of plastics.

In 2020, there were notable changes at the executive-management level in all areas of the European plastics industry. A change of generation took place at packaging manufacturer Alpla, where CEO Günther Lehner handed the rein over to his son, Philipp. CCO Karl Deily decided to retire after 40 years at Sealed Air. Former RPC boss Pim Vervaat became the new CEO of Constantia Flexibles.

In the machinery sector, the appointment of Michael Ruf as the new head of KraussMaffei is noteworthy.

On the production side, Geir Tuft took over the management of European PVC market leader Inovyn, as Steve Harrington is now CEO of styrenics producer Ineos Styrolution. PA supplier Domo Chemicals appointed Yves Bonte as its new CEO, and there was an unexpected management shake-up at DuPont. Christopher McArdle was named VP of polyolefins strategy at Borealis.

In Brussels, Virginia Janssens became the managing director of PlasticsEurope, while Covestro CEO Markus Steilemann took over as the new president of the producers’ association. Tragically, the managing director of the association’s German branch Rüdiger Baunemann passed away in April. Oliver Möllenstädt left German plastics converters association GKV.

Looking at the top 50 of PIE’s most-read articles in 2020, it doesn’t come as a surprise that there are a lot of polymer-price and feedstock market reports way up there. But our readers were also interested in coronavirus-related topics, automotive, plastics regulations and recycling. Here are PIE’s top three articles, apart from polymer prices and forces majeures:

Automotive industry (4 June 2020): Unreliable supply chains, volatile demand and a projected sales decline of 20-30% were placing a heavy burden on the automotive sector. Then came the Covid-19 crisis.

Bioplastics (25 February 2020): Together with German nova-Institut, European Bioplastics published a report on biopolymers’ growth. Driven by bio-based PP and PHA, global capacity is projected to grow to about 2.4m t in 2024.

EU Plastics Tax (12 October 2020): European Parliament greenlit the EUR 800/t levy on non-recyclable plastic packaging, passing a resolution to introduce new sources of revenue – so-called “own resources” – in order to finance the EU Covid-19 recovery funds.

Interestingly – yet not surprisingly – our most popular Plastic Fantastic in 2020 was also pandemic-related.

For our top 10 articles for 2020 (without polymer price reports; sorted by date) please click on the “Read more at PIE” button on the right.

This turbulent year will soon be over. Across the globe, the coronavirus crisis has hit industries hard, with many fateful consequences. Numerous trade fairs and events were cancelled or changed into virtual formats. The entire event-management sector came to a screeching halt.

The plastics industry also saw significant losses, as shown by the coronavirus crisis-related PIE flash survey in May and the Covid-19 survey carried out by PIE’s sister publication KI – Kunststoff Information and K-PROFI in October. Meanwhile, many companies believe that they have already bottomed out, and are cautiously optimistic about 2021.

This has been an exciting year for the KI Group as well, with some good experiences that we can be happy about, despite the pandemic and its impact:

Our new KI Group website went online in 2020, for instance, and we could establish our CPD division Knowledge & Training with its range of seminars for plastics professionals in English and German. The start of the seminars was successful, which encouraged us to expand the format in 2021.

All this would not have been possible without our loyal readers and customers. Thus, we would like to take this opportunity to thank you sincerely for your support this year!

No doubt, we will hear from each other next year, but for now, let us wish you all the best for the Christmas season and the New Year. Stay safe!

Your PIE Editorial Team